Qingzhou Haozhang industry and trade blower

2020-10-23

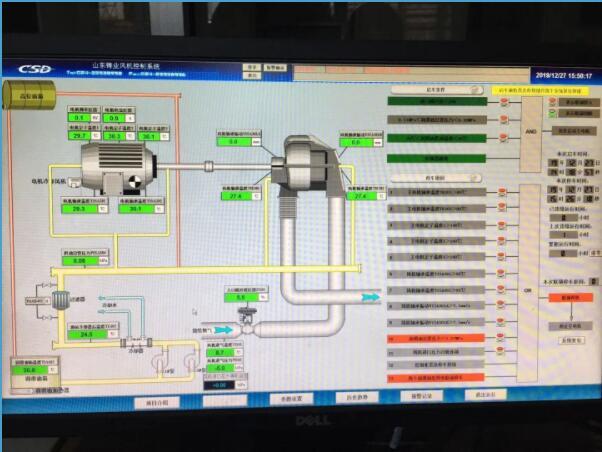

This system is a blower control system, mainly including fan, motor, oil station, electric actuator and other process package engineering. After fully considering the working characteristics of each equipment and the overall process operation requirements, and carried out targeted and reasonable system configuration.

The low pressure part of the system adopts GDD type operating cabinet. The operating surface is equipped with status indicator, start-stop switch and transfer switch, and the main circuit components such as low-voltage circuit breaker, contactor and thermal relay are installed in the cabinet. Auxiliary engine control is divided into two forms, automatic control and manual control. The automatic control is completed on the automatic control system PLC, and the manual control is completed on the field operation box.

The unit control system is composed of a primary instrument + a control system. The primary instrument is placed on the equipment body or the local pipeline to collect the signals required by the unit and send them uniformly to the control system. The control system processes the signals according to the control requirements of each equipment and the process operation requirements to complete the online control of the unit.

The control system adopts SIEMENS S7-300 series PLC products, and the CPU has network communication function to complete the data collection, storage, process adjustment, logic control, network communication and protection functions of the unit. An operator station is set up in the system to complete the system programming configuration, online modification, signal coercion, policy and debugging, and complete the corresponding monitoring, operation, external communication and protection during the unit operation. The complete control system is equipped with a set of PLC control system cabinet and a set of low-voltage system cabinet.

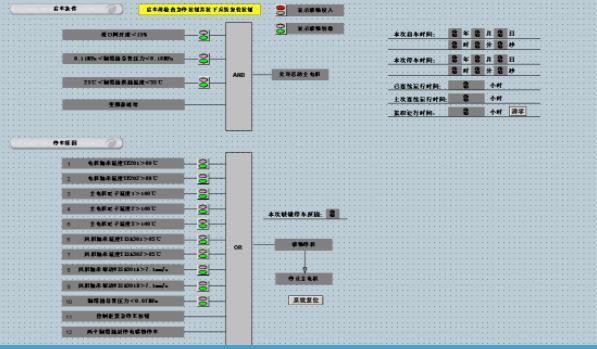

The configuration screen of the control system includes the main screen, flow chart screen, control loop adjustment screen, alarm interlock screen, starting condition screen, real-time and historical trend screen, engineer debugging screen, etc. The following is the flowchart screen

Briefly understand the process requirements of the unit and the functions that the software can achieve. The starting of the blower needs to meet the following conditions;

1, the inlet valve is slightly open, that is, the inlet flow is small. The control of the inlet valve requires the use of automatic and manual control methods in the program, so as to achieve the air volume and wind pressure required by the process.

2, the lubricating oil temperature is normal. Control of lubricating oil motor heater, when the lubricating oil temperature is lower than a certain value, the lubricating oil heater automatically starts, when the lubricating oil temperature is normal, the lubricating oil heater automatically stops.

3, the oil pressure is normal. In order to ensure the normal pressure of lubricating oil, the lubricating oil station adopts two pumps (mutual active and standby) control mode. When the fan is running normally, it is necessary to ensure that one lubricating oil pump is running and the other one is in standby state. When the pressure falls below a certain value, the standby pump starts automatically.

When all the conditions have been met, the system issues a command to allow the start, the unit starts, the start is manual start. When the main motor works normally, press the automatic operation button to carry out the automatic operation mode.

The stop of the blower is divided into two cases: normal shutdown and interlock shutdown. Normal downtime is manually stopped by the operator. Interlocked downtime is downtime caused by the operator pressing the emergency stop button in an emergency and by the safety detection function. And the automatic control system has the accident safety detection system, the first shutdown reason analysis of the source of the unit failure, to determine the fault point of the accident, convenient for customers to find equipment failure.

The alarm of the blower system, according to the process conditions, implements the over-limit alarm for each monitoring point. Among them, such as bearing vibration, bearing temperature and oil pressure and other important measuring points are stopped and interlocked. That is, when the bearing vibration exceeds a certain range, the bearing vibration alarm will be issued, and the effect of stopping the fan will also be realized, so as to achieve the role of protecting the equipment.

There are many similar blower projects of Chuangstar (Liaoning) Environmental Protection Engineering Co., LTD., including anti-surge control systems, which have formed mature technical specifications. According to the different requirements of users, different processes and functions are designed.

Typical Performance

联系我们

Address:Room 1201, Chung Chi International Building, 3 South five road, Heping District, Shenyang

Zip Code:110000

Tel:024-2393 8998

Fax:024-2393 8996

Website:http://www.csd.cn

E-mail:info@csd.cn

Mobile website

Contact us