Qidong Huafeng microfiber phase II DMF recovery control system

2020-10-23

1. Purpose and significance of DMF recovery

In the manufacturing process of microfiber leather, DMF is used as a solvent to dissolve polyurethane resin. In this process, DMF is easily dissolved in water, and DMF wastewater in the manufacturing process of microfiber leather is generated.

With the expansion of the scale of enterprises and the enhancement of human awareness of environmental protection, coupled with the requirements of synthetic leather production costs and the continuous development of DMF recovery technology, it is necessary to recover DMF from DMF wastewater for reuse. The purpose of this device is to recover DMF, so that enterprises have better economic benefits, but also has important significance for environmental protection.

2.DMF process and recovery principle

The DMF recovery device can be divided into seven parts, such as two-stage concentration under pressure, feed evaporation, slag removal, rectification under pressure, deacidification under pressure, formic acid neutralization and deamination of tower top water.

During recovery, DMF and water should be separated by distillation. The DMF after dehydration and purification contains a small amount of formic acid, and the DMF containing formic acid is removed by thermal decomposition method. The solid in DMF wastewater was removed and the top water of the tower was separated from dimethylamine.

3. Composition of the control system

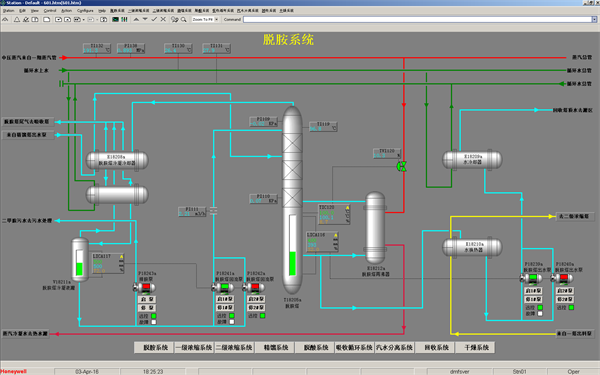

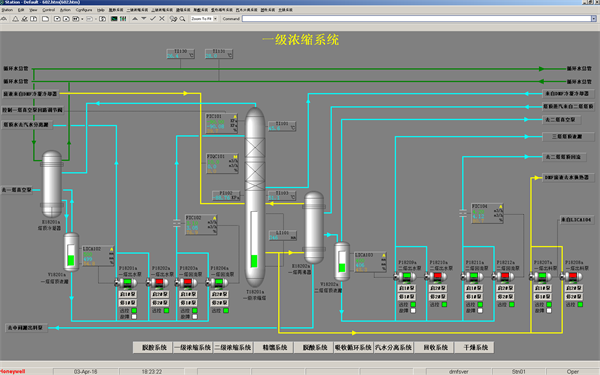

The control system adopts HONEYWELL PlantCruise products.

The operation station screen is as follows:

Typical Performance

联系我们

Address:Room 1201, Chung Chi International Building, 3 South five road, Heping District, Shenyang

Zip Code:110000

Tel:024-2393 8998

Fax:024-2393 8996

Website:http://www.csd.cn

E-mail:info@csd.cn

Mobile website

Contact us