Yinchuan crystal material base sewage treatment station control system

2020-10-23

This project is the sewage treatment station control system of Yinchuan Economic and Technological Development Zone crystal material industry development base project

Yinchuan crystal material base sewage treatment station control system project description

I. Introduction of the project

(1) Project overview

The sewage treatment station is mainly responsible for the sewage generated by the processing workshop, the raw material cleaning workshop, the insert locomotive room and the diamond wire cutting workshop.

(2) Process flow

1, processing workshop wastewater treatment is the use of coagulation air flotation process. The whole process of coagulant flotation is to add the prepared coagulant into the wastewater by quantitative dosing, and realize the rapid and uniform mixing of water and pharmaceutical agents in a certain way, and then enter the air flotation tank for solid-liquid separation. The air flotation is composed of two processes: coagulation and air flotation.

2, raw material cleaning workshop wastewater treatment is the coagulation process. A chemical agent (often called coagulant) is put into the wastewater to make the colloidal suspended particles or emulsion pollutants that are difficult to precipitate in the water lose stability, and polymerize and bond with each other to form larger particles or flocculents, so that the pollutants are easier to naturally sink or float and be removed. Coagulants can reduce the turbidity and chroma of sewage, remove a variety of polymer substances, organic matter, some heavy metal poisons and radioactive substances.

3. Air flotation process is adopted for the treatment of waste water between insert locomotives. In the process of air flotation, the fine bubbles first adhere to the suspended particles in the water, forming a "bubble-particle" complex with an overall density less than that of water, so that the suspended particles float together with the bubbles to the water surface, thus completing solid-liquid separation.

4. The wastewater treatment of diamond wire cutting workshop is first treated by diaphragm filter press, and then discharged after being treated by air float pool and MBR pool.

2. Control system description

(1) Composition of control system

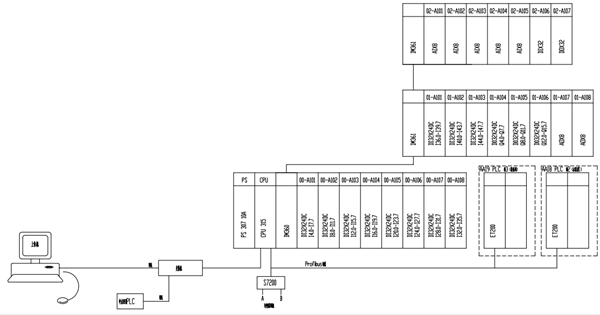

The control system includes PLC control cabinet, field instrument, field operation box, operation table, etc. The control system is controlled by PLC program and monitored by host computer. PLC adopts S7-300 series products of Siemens. System software: Configuration software is WINCC V7.3, programming software is STEP7 V5.5. The system is configured with two operating stations, one industrial computer, two monitors, and dual screen display.

(2) Introduction to network topology

(3) Introduction to the characteristics of the control system

1. Lift pump

Lift pump according to the water tank level chain control, the liquid level reaches the high level when the start, stop when the liquid level reaches the low level, when the liquid level is low shall not start. Automatically start the backup pump when the main pump fails.

2, dosing pump

The dosing pump can automatically start and stop according to the pH value of the coagulation reaction tank. The target pH value and the pH value of the start-stop dosing pump can be set on the upper computer.

3, mud pump

The mud pump adopts regular start and stop, the start time is adjustable, and can be set on the upper computer. After the primary pump runs for 24 hours, the standby pump is switched over. The switching time can be set on the upper computer. If the primary pump fails, the standby pump is automatically switched over.

4, high efficiency sedimentation gas floating tank

The start and stop of the air float tank is linked with the lifting pump of the water regulation tank. The system starts when the pump starts, and the system mixer stops after a delay of 5min.

5, MBR suction pump

MBR pool is equipped with 5 level control points: ultra high level, high level, medium level, low level and ultra low level. The MBR suction pump realizes automatic adjustment and automatic start-stop control according to these 5 level control points.

6. Membrane pool blower

When the membrane assembly is operating normally, the membrane pool blower is always running. When the MBR tank level is at ultra-low level, the membrane tank blower automatically enters the low-load mode, that is, it runs for 5min and stops for 55min. When the MBR suction pump is abnormal and stops running for more than 15 minutes, the membrane pool blower will automatically stop to avoid long-term air aeration and damage to membrane components. The above time Settings are adjustable.

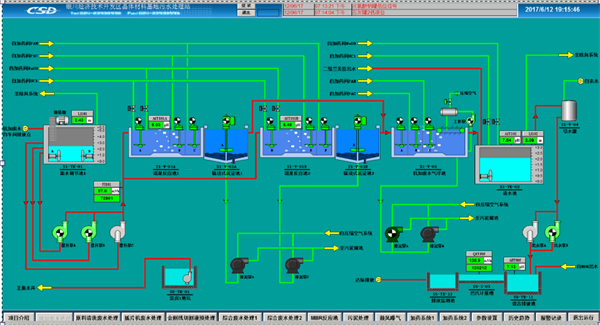

(4) Running picture

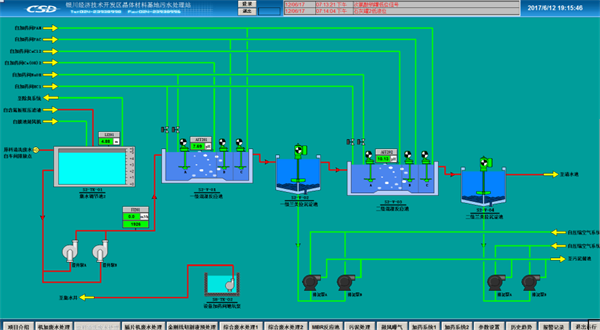

Figure 1-2 machine wastewater treatment screen

Figure 1-3 Raw material cleaning wastewater treatment screen

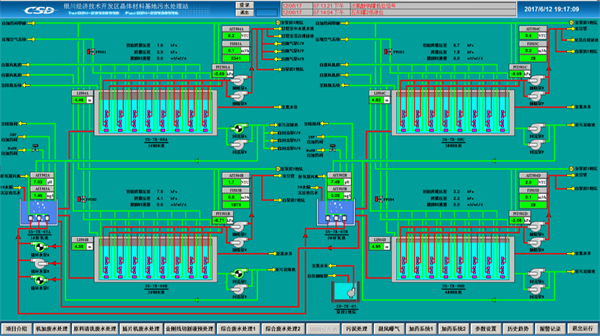

Figure 1-4 MBR reaction tank

Typical Performance

联系我们

Address:Room 1201, Chung Chi International Building, 3 South five road, Heping District, Shenyang

Zip Code:110000

Tel:024-2393 8998

Fax:024-2393 8996

Website:http://www.csd.cn

E-mail:info@csd.cn

Mobile website

Contact us