Dust removal control system of Guangxi Shenglong coke oven ground station

2020-10-23

Guangxi Shenglong coke oven ground station dust control system project description

I. Introduction of the project

(1) Project overview

This project is a 2*60 hole 5.5m side loading coke oven control system for coke discharging, coal loading and coke pushing. There are three dust collectors in total.

(2) Process flow

1. Coke discharge and dust removal process: The coke dust collected by the dust collection hood of the coke stopping vehicle during coke discharge is introduced into the dust collection dry pipe through the smoke guide pipe and butt sleeve connected to the dust collection hood through the conversion equipment, and then transported to the ground dust collection station on the coke side, where the flame arrester is separated by intermittent high temperature dust cooling and the bag filter is processed and filtered by the fan chimney.

2. Coal loading and dust removal process: The dust generated in the carbonization chamber during coal loading is collected by the dust collecting cover on the side of the machine, connected with the fixed lifting valve group through the smoke exhaust pipe, enters the coal loading ground station, is purified by the flame arrester and the pulse bag dust collector after pre-spraying treatment, and is discharged to the atmosphere by the dust removal fan through the chimney.

3, push coke dust removal process: when picking the door and pushing coke, the flue gas overflows from the carbonization chamber, is inhaled by the dust collecting cover of the push coke car, and then enters the dust collecting pipe through the fixed lifting valve, is sent into the pulse bag type dust collector after purification, and is discharged to the atmosphere by the dust removal fan through the chimney.

After the dust removal, the flue gas emission concentration is less than 10mg/m3, and the dust collected by the dust collector is transported to the dust bin by the scraper conveyor, and the dust in the dust bin is regularly humidified by the humidifier and unloaded into the car.

2. Control system description

(1) Composition of control system

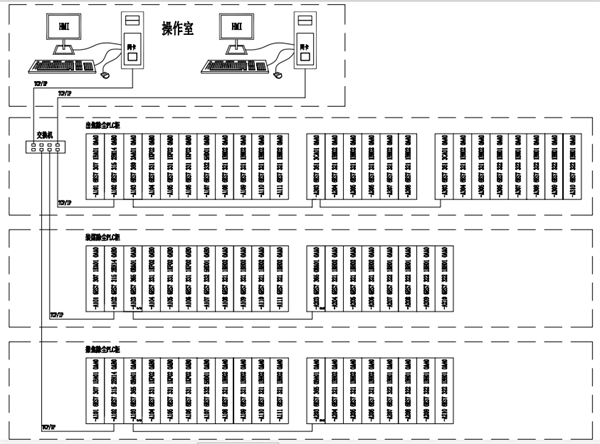

The control system includes PLC control cabinet, GGD electric control cabinet, field instrument, field operation box, operation table, etc. The control system is controlled by PLC program and monitored by host computer. PLC adopts S7-300 series products of Siemens. System software: Configuration software is WINCC V7.4, programming software is STEP7 V5.5. The system is configured with 2 operating stations, and each operating station is configured with a set of industrial computer.

(2) Introduction to network topology

The communication between the host computer and PLC adopts the Ethernet communication protocol. The network topology diagram is as follows:

Figure 1-1 Network topology

(3) Introduction to the characteristics of the control system

1. Vibration and dust removal

The remote cleaning part of the bag dust collector mainly has four control methods: manual, timing, differential pressure and forced:

Manual control: Click the manual cleaning button, and then click the manual screen, the manual cleaning operation screen will pop up. The manual mode needs to select the warehouse room first, such as click the 1# button below the warehouse room, and then click the pulse valve to select the 1#~15# button below, and respectively spray the 1#~15# pulse valve of the 1# warehouse. The blowing in other chambers is the same as in chamber 1#. If you need to stop the manual spray control, you can click the Cancel chamber button.

Timing control: When the set time is reached, the pulse valve will start to spray, according to the sequence of chamber number, automatic spray from 1# chamber first, then automatic spray from 2# chamber, and so on. When all chambers are finished spraying, the timing will be re-timed for the second spray, and the cycle will continue in turn until the manual ash cleaning button or the spray emergency stop button is clicked. Stop the circulation blowing. Timing time, pulse valve operation time and pulse valve interval time can be modified in the parameter setting screen.

Differential pressure control: Click the differential pressure cleaning button, and the differential pressure value to start the differential pressure injection can be set in the parameter setting screen. The differential pressure value to start the injection of the differential pressure control for the dust removal project is 1600Pa. When the differential pressure is higher than 1600Pa, the cyclic injection begins in the same way as the regular cyclic injection. Automatically stop blowing when the differential pressure is less than 1000Pa.

Force control: Click the force cleaning button to start the cycle spray, the way is the same as the regular cycle spray. After the completion of the first cycle injection, start the second cycle injection, and then continue the cycle injection until clicking the manual button or the emergency stop button can stop the cycle injection.

2. Ash unloading part

When the high level meter on the ash hopper sends out the ash discharge signal, the ash discharge system is started, and the ash discharge system is stopped at the low level. Ash discharge is started regardless of the signal at the high level, and stops regardless of the signal feedback at the low level.

The middle ash bin is only set high material level, high material level signal will start unloading ash, manual stop.

3, fan speed control

The speed of fan is controlled by frequency of inverter.

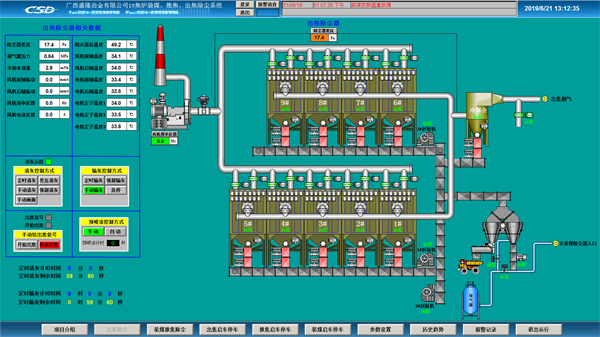

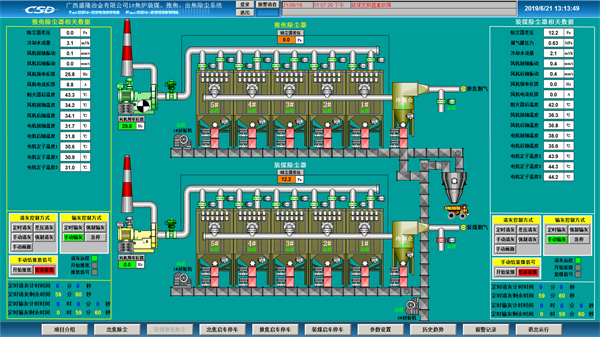

(4) Running picture

Figure 1-2 Taking out coke and removing dust

Figure 1-3 Coal loading, coke pushing and dust removal

Typical Performance

联系我们

Address:Room 1201, Chung Chi International Building, 3 South five road, Heping District, Shenyang

Zip Code:110000

Tel:024-2393 8998

Fax:024-2393 8996

Website:http://www.csd.cn

E-mail:info@csd.cn

Mobile website

Contact us