Shandong Hengxin ground station dust removal system

2020-11-18

This system is a control system for the ground coal charging and dedusting station of coke oven, which mainly includes a complete set of process control system projects such as coal charging, coke discharging, water sealing tank and adsorption bin system.

Hardware composition:

The hardware system consists of 2 PLC control cabinets, 1 industrial computer and 1 PLC control system. A SIEMENS PCS7-410 PLC control system is installed in the PLC control cabinet to monitor the running state of the dust collector and various process parameter variables

According to the actual situation of the customer and the compatibility of the whole system, the control system chooses the PCS7-410 system of Siemens, the engineer and operator workstation chooses the industrial computer system of DELL, the communication mode between the two is EtherNet in the Siemens industrial communication network, the communication rate is fast, and the scalability is good. Thus, the information of this system is guaranteed to be real-time, fast, stable and safe.

SIMATIC PCS 7 - a truly modern DCS system HMI with multi-user capability HMI components, high capacity architecture, hot swappable (modules inserted and removed on the fly), extendable/modified on the fly, integrated fail-safe technology, intelligent field device/driver integration, batch engineering, and more. Comprehensive, integrated SIMATIC PDM software with import/export function, application of graphical and PLT-oriented tools for centralized parameterization of intelligent field equipment, parallel engineering functional formulation is unit - and device-independent, hierarchical formulation, in accordance with ISA S88.01 and 21 CFR Part 11 specifications

Communication system:

The industrial computer uses the industrial control computer of DELL Company, which communicates with the lower machine (DCS control system: CPU410-5H in PCS7 of Siemens company) to monitor and control the dust collector and various parameters related to the dust collector.

Software system:

In the software system of operator station and engineer station, the following operating software and monitoring software are:

System software: Microsoft's Windows 7;

Development software: SIEMENS PCS7 9.0 SP1 software;

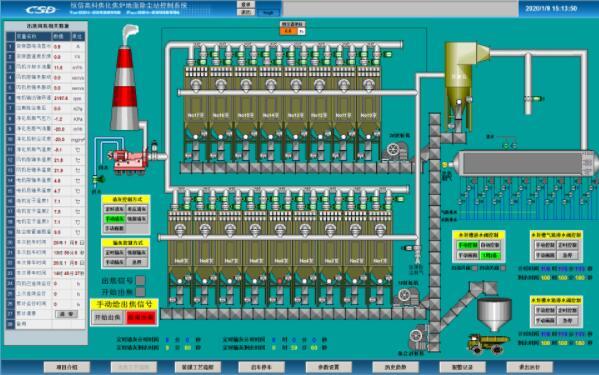

Overview of the monitoring screen:

In order to meet the needs of users, from the perspective of user operation, we have designed several groups of screens:

Project introduction, coke out system, coal loading system, start and stop, parameter setting, historical trend, alarm record, exit operation

Coal loading system:

Coal charging system overview:

According to many years of practical experience, ash cleaning control and ash transport control have manual and automatic control modes of upper machine, and the automatic control of ash cleaning includes: timing, differential pressure and forced three control modes; Ash transport automatic control also includes: timing, forced two control modes, for users to choose according to the actual situation.

Coke output system:

Overview of Coke extraction system:

According to many years of practical experience, ash cleaning control and ash transport control have manual and automatic control modes of upper machine, and the automatic control of ash cleaning includes: timing, differential pressure and forced three control modes; Ash transport automatic control also includes: timing, forced two control modes, for users to choose according to the actual situation.

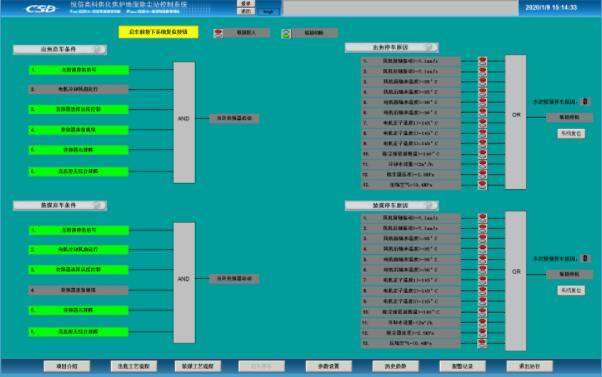

Start and stop:

Starting and Stopping Overview:

When starting conditions are met (green state), the frequency converter allows the start signal to be sent; If any of the parking interlocks appear (red state), the interlock stop signal will be issued, and the serial number of the corresponding stopping reason will be recorded for the user to troubleshoot the fault. Users can invest and cut the interlock independently according to the actual situation.

List of measuring points:

Survey point list overview:

Upper range limit: indicates the upper range limit of detection data

Lower range limit: indicates the lower range limit of detection data

Alarm interlock setting value:

L: low alarm value, when the current value is lower than this value, the low alarm is generated, and the buzzer generates an alarm.

H: high-limit alarm value. When the current value is higher than this value, the high-limit alarm is generated, and the buzzer generates an alarm.

L L: low threshold alarm value. When the current value is lower than this value, low threshold alarm or interlock parking will be generated, and the buzzer will generate alarm and sound.

H H: high-high-limit alarm value. When the current value is higher than this value, high-high-limit alarm or interlock parking will be generated, and the buzzer will generate alarm.

LL and HH at the end of the table: indicate the alarm value when an interlock stop occurs, and the buzzer generates an alarm sound.

next page

next page

Typical Performance

联系我们

Address:Room 1201, Chung Chi International Building, 3 South five road, Heping District, Shenyang

Zip Code:110000

Tel:024-2393 8998

Fax:024-2393 8996

Website:http://www.csd.cn

E-mail:info@csd.cn

Mobile website

Contact us